In October2024, Changan Automobile, a leading Chinese automobile manufacturer, unveiled its Digital Intelligence Factory during the 4th Changan Tech Ecosystem Conference. This factory, powered by 5G and AI, has transitioned to the mass production phase, signaling the next step in the deep integration of 5G within the automotive industry.

Digital Intelligence Factory Unveiling at the4th Changan Tech Ecosystem Conference

The Changan Digital Intelligence Factory is a joint effort by China Unicom, Changan Automobile, and Huawei. It serves as a showcase for 5G future manufacturing, highlighting the latest explorations and achievements of China Unicom and Changan Automobile in applying information technologies to advance the real economy.

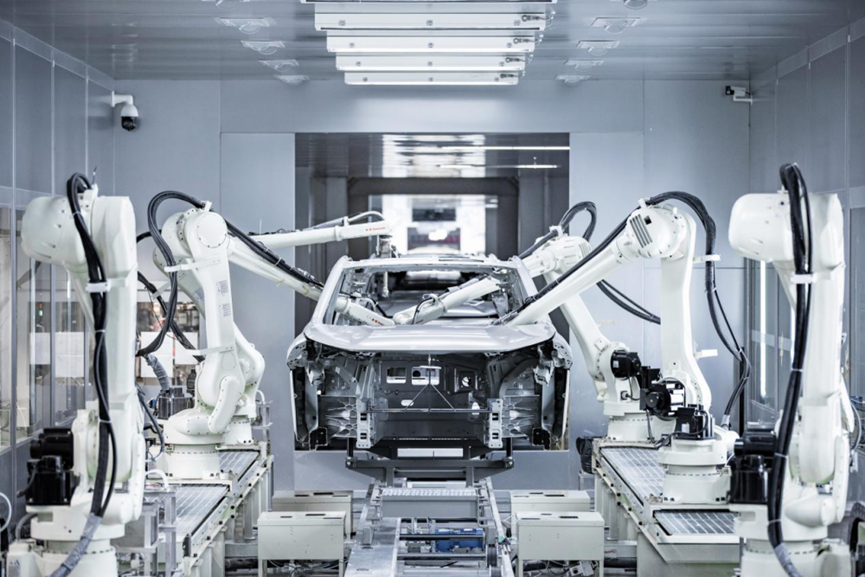

Painting line in Changan Digital Intelligence Factory

The Changan Digital Intelligence Factory, located in Yubei District, Chongqing, features hundreds of industrial robots that operate continuously. The factory has achieved full 5G coverage across seven workshops, 87 production lines, and more than 1,000 processing and production scenarios. This extensive 5G network connects dozens of manufacturing systems to a unified digital base, facilitating the transmission of millions of production instructions in real time. This supports the operations of services related to safety, quality, delivery, costs, personnel, equipment, and environment.

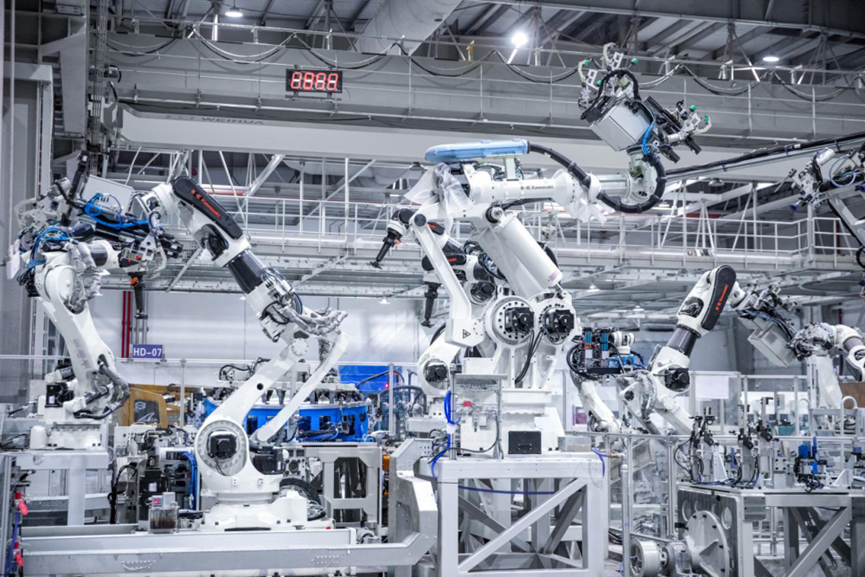

Welding line in Changan Digital Intelligence Factory

"To achieve smooth data transfer and modular software development, we have developed data and software governance tools tailored to the unified digital base, and built a next-generation industrial-control IoT platform that integrates data collection and control capabilities. Coupled with the flexible 5G network, these innovations support accurate delivery of instructions to workstations and machine stations alike," said a director from China Unicom Research Institute. The director also detailed how China Unicom has leveraged5G to construct a comprehensive information network for the factory and delved into core production processes to promote the continuous digital transformation of the entire manufacturing system.

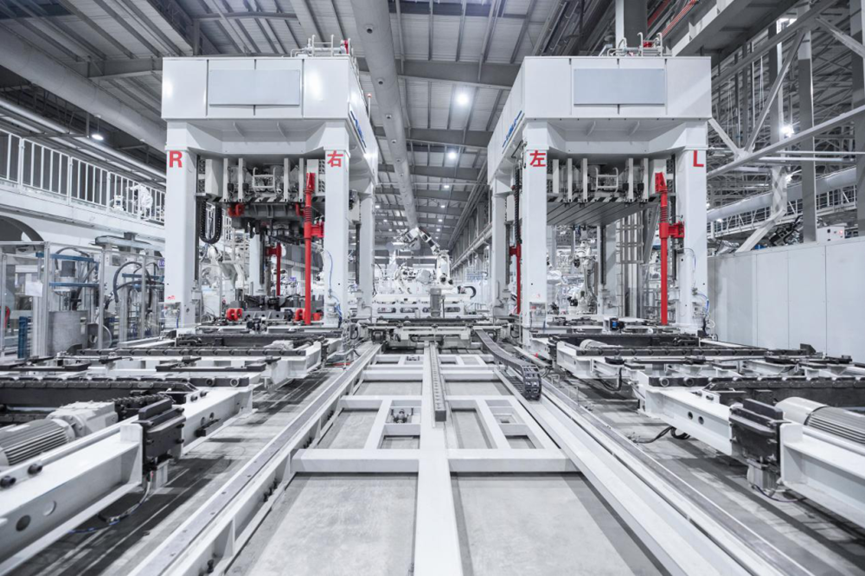

Mold stamping line in Changan Digital Intelligence Factory

Fully connected by 5G and powered by AI, this factory boasts over 800 intelligent devices, 1,400 robots, 650 intelligent AGVs, and 200 fully-automated workstations. By working together, these help achieve 100% automation of critical processes. Furthermore, the factory uses an industry-leading "AGV+ robot + unattended warehouse" model to establish a smart logistics system featuring flexible routes and device expansion. The factory leverages China Unicom's latest 5G and industrial control IoT technologies to connect production devices, personnel, materials, and process data, showcasing the large-scale application of end-to-end 5G features in the automobile industry. Four 5G macro base stations and 329 5G micro base stations have been deployed to support the networking of more than 12,000 devices across 103 scenarios, facilitating data collection efficiency of 1 million points per second.

Based on China Unicom's QingTian 5G+ unified industrial control platform, Changan Automobile has developed a consumer-to-manufacturer (C2M) model that benefits from flexible production scheduling, agile manufacturing, and smart logistics. This model marks a shift from inventory-based manufacturing to order-based manufacturing, enabling Changan Automobile to quickly respond to market requirements, mitigate inventory risks, and improve production efficiency.

The factory's flexible production lines have industry-leading commissioning and switching efficiency, making it possible to simultaneously manufacture multiple brands and models of vehicles and meet diverse customers' needs. Users can place orders online and select their preferred vehicle model, power type, exterior color, interior color, and configurations, as well as delivery time.

"With intelligent devices, fully-automated workstations, and automated critical processes, we can roll a vehicle off the production line every 60 seconds on average," stated a director of Changan Digital Intelligent Factory. The director continued, "We have achieved 100% on-time delivery rate, 100% traceability of critical parts, and over 99% planning accuracy. The time taken to ramp up production has been reduced by 20%, and the order delivery period has been cut by 3 to 7 days."

Looking to the future, the head of China Unicom Chongqing's 5G Converged Innovation Center reaffirmed the company's commitment to driving the digital transformation of the manufacturing industry alongside Changan Automobile and other partners. Together, they are aiming to build a 5G + Industrial Internet framework that will help upgrade China's entire automobile industry.